CAGS FIRE SYSTEM

Technical Service with over 25 years of expertise in industry and defence sector, as well as over 12 years of competence in delivering solutions for Condensed Aerosol Generation Fire Suppression System In Bharat (India)

About Us

Introduction

After Halon extinguishers were phased out in the 1980s, Condensed Aerosol Generating Suppression (CAGS) Fire Extinguishing technology, which had originally been developed as a Halon substitute, has received a lot of attention. CAGS Fire extinguishing agents is most efficient, unlike traditional inert gas, foam, water mist, and Halon fire suppression agents, do not need to be driven out by pressurised gases and can extinguish class A, B, C, D, E, and F fires at 30 to 120 g/m3, which is significantly less than that of conventional extinguishing agents like CO2, HFC227ea, IG55, IG100, FK-5-1-12, etc…

History

Developed nearly 30 years ago in the Soviet Union during solid-fuel rocket research, this Russian technology extinguishes fires by disrupting the chemical combustion process rather than targeting heat, fuel, or oxygen like conventional extinguishers. CAGS emerged as a Halon replacement, offering safe and effective fire suppression when properly designed. After the USSR’s collapse, technology owners licensed international companies to develop and distribute these systems, providing access to potassium-based compounds from Russian sources. However, Generation 1 CAGS contained Nitrocellulose and Chlorine traces, limiting its use to specialized applications. Licensees marketed these with minimal refinement or modified activation mechanisms and body structures

Re-Engineered

CAGS fire extinguishing technology evolved from Generation-I oil tank suppression to Generation-II (Aerosol “G”), a non-toxic, non-corrosive system for diverse applications including communication base stations, electric power facilities, petroleum industry, spacecraft cargo rooms, weapons warehouses, mobile engine rooms, and metallurgy. Industrial and defense designs achieved over 85% discharge efficiency with a gross-to-active compound weight ratio not exceeding 4:1, making canisters lightweight enough for secure wall or ceiling mounting even under strong vibrations or navigation conditions. This advancement expanded CAGS .

Our Core Value

Reliable Engineered Solution

Customer First Service

Make in Bharat

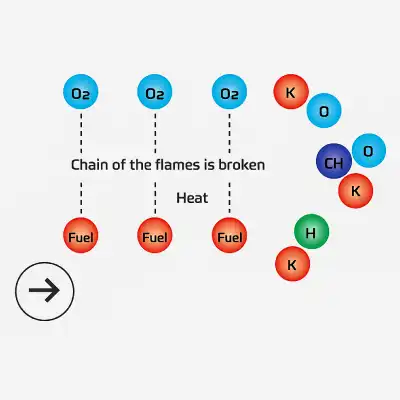

Principal Of Extinguishing

Aerosol suppression disrupts radicals, neutralizes fire, and cools effectively.

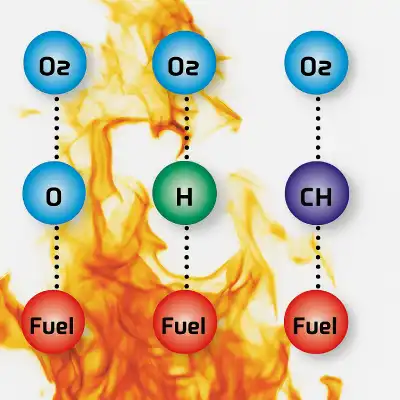

Fire Radicals

Fire propagation radicals (OH, H, and O) are essential elements in sustaining fire. These reactive species continuously fuel combustion reactions. Condensed Aerosol Generating Fire Suppression Agents primarily act by chemically interfering with these free radicals within the fire zone, thereby disrupting the ongoing chain reaction that maintains the fire.

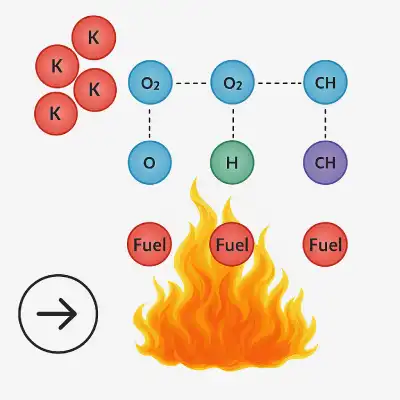

Condensed Aerosol Agent

The Condensed Aerosol Generating Suppression agent is released as microscopic solid particles, composed mainly of potassium radicals. When introduced into the blazing zone, these particles interact with the fire radicals produced during combustion—such as hydrogen, oxygen, and hydroxyl radicals—and neutralize them. Due to their wide surface area, these fine aerosol particles effectively trap and deactivate radicals, making them excellent extinguishing agents.

Cooling Effects

Coolants in Condensed Aerosol Fire Suppression systems play a vital role in lowering aerosol temperature, which helps prevent reignition and secondary fire hazards. The cooling process occurs through coolant vaporization and endothermic chemical breakdown, absorbing heat and stabilizing the environment after suppression.

Advantages Of CAGS System

- Non Toxic

- Fit & Forget

- No Re-ignition

- Non Corrosive

- Non Conductive

- No Water damage

- No Pressure built-up

- No Oxygen depletion

- Zero Pressure storage

- Fail Safe & Highly reliable

- No high pressure Cylinder

- No Pipe work & Manifolds

- Wall/Ceiling Mounted

- Large sizes & capacity

- Suitable fire class A, B, C, E, F

- Zero Ozone depletion

- Zero Global Warming

- Environment-friendly

- Prevent Flash-over

- Prevent Back-draft

- Easy to find fire source

- Shelf life not less than 15 Yrs

- Fixed / Portable Options

- Self activation >300° C

Applications

Battery Energy Storage

Transformer Rooms

Duct Protection

Flammable Liquid Storage

High Rise Building

Server Room / Data Centre

Gas Turbine Enclosures

Switchgear Rooms

Generator Rooms

Engine Compartments

Wind Turbines

Machinery and Engine Room

Firefighter First Responder

Dust Collections

Select The Right CAGS Fire System

Aerosol Compound Type Verification

Check the kind of aerosol compound type (1st / 2nd Generation). Condensed Aerosol extinguishing compound should be free of chlorine, nitrocellulose, and pyrotechnics.

Active Compound Extinguishing Concentration and Performance Parameters

Check the Active Compound Extinguishing Concentration (Check the pre-burn time, soak time, and aerosol density depending on the fire class specified in the Notified Body Test Report).

Discharge Efficiency Confirmation

Check the product’s discharge efficiency that should not be less than 85%, which may be confirmed using the table “Efficiency of the generator types” from the notified body test report.

Toxicity Compliance and Non-Toxic Certification

For Aerosol Compound Acute Oral, Acute Inhalation, Acute Dermal Toxicity, and Acute Ocular (Eye) Toxicity, look for a Non Toxic Certificate from an International Testing Lab or a NABL Accredited Lab.

Hold Time / Re-Ignition Prevention as per ISO 15779

According to ISO 15779, the canister shall have a hold time (Re-Ignition Prevention) of more than 25mts to stop re-ignition, and the relevant notified body report should be confirmed.

Gross Weight and Active Compound Ratio Verification

Check the gross weight of the canister, which should be lighter in weight, with maximum active compound weight to gross weight ratio of 1:4 being optimum.

Service Life Verification

Check the service life, which should not be less than 15 years, and verify the appropriate notified body test result.

Operating Temperature Range Compliance

Best condensed Aerosol has a wide working temperature range of -50 degrees Celsius to +75 degrees Celsius

Effectiveness Against All Fire Classes (A, B, C, and E)

The system must be effective against all fundamental fire classes (A, B, C, and E).